Process Optimization

Process Optimization

Enhance your facility’s productivity with DKC’s Process Optimization Consultancy.

Led by industry veteran Pieter de Kort, our affiliate experts team tailors optimisation solutions. We use proven techniques such as Six Sigma and Lean, Designed Experiments, but most of all we use our Expertise and “Applied Common Sense” to ensure practical, cost-effective, and safe techniques to optimize our client’s processes.

Experience has shown that e.g. productivity improvement of more than 20% is often possible without large investments.

Start to Improve your efficiency today – contact us for a personalized consultation

Six Sigma – Variation is the enemy!

Six Sigma is a process improvement methodology centered on minimizing defects and variations. It employs data-driven analysis and statistical methods to boost efficiency, improve quality, and enhance customer satisfaction, resulting in cost savings for organizations

Fight the variations of your process with DKC’s expertise!

Let us be your ally in analyzing and conquering process variations. Together, we’ll elevate your efficiency and ensure a smoother, more reliable operation. Take the first step toward precision and excellence.

Lean – Eliminate Muda/Waste

Lean optimization, rooted in Lean principles, targets waste reduction (Muda in Japanese) to enhance efficiency and customer value. It streamlines processes by eliminating non-value-adding activities, fostering continuous improvement and just-in-time production for a more resource-efficient and customer-centric approach.

Unleash the power of efficiency, and eliminate Muda with DKC!

Say goodbye to wasted resources and hello to streamlined perfection. Our expert team is ready to dive deep into your processes, identifying and eliminating every trace of Muda. Transform your operations, boost productivity, and watch your success soar! Trust DKC to make waste a thing of the past – because your efficiency is our priority!”

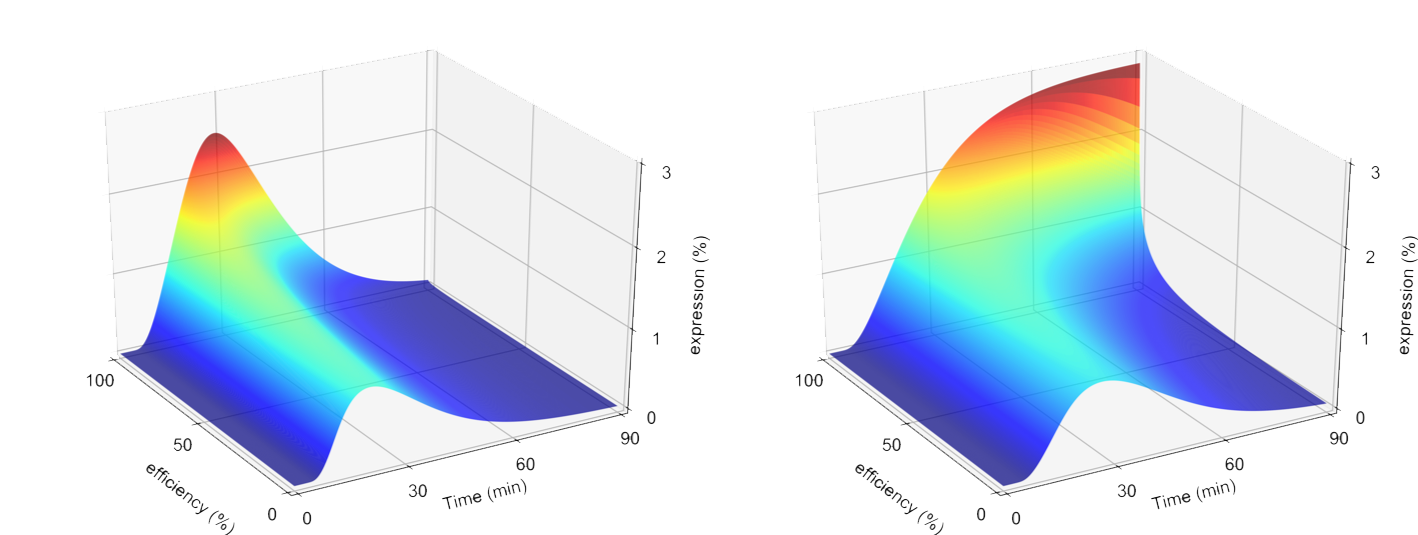

Design Of Experiments

Batch Cycle Time Reduction

Many batch operations are running sub-optimal as different process steps are done in sequence. At DKC we have decades of experience to stream line batch process, by doing steps in parallel, in a different order or just faster. This is applicable for manual activities as well as automated process steps.

Improve production capacity by reducing Batch Cycle Times

Experience has shown that 20 to 30% productivity improvement are often feasible without large investments.

Incident Investigation

DKC’s Incident Investigations go beyond just safety – we tackle production issues and quality glitches too. Our thorough investigations find out exactly what’s causing problems, so together we can fix them with practical solutions. At DKC, we’re all about solving operational challenges and making things run smoothly.

Investigate, Analyse, Solve (for Good)

Elevating Processes, Empowering Solutions

Enhancing processes isn’t always about fixing issues – it’s about a strong desire to do better. At DKC, our expertise spans various industries, backed by a solid foundation in chemistry, polymer science, mechanical engineering, and physics. With our creative approach and commitment to success, we partner with clients to craft project-based improvements, turning ambition into tangible results.

Turning Ambition into Process Excellence!

Improve your safety program today.

Just starting out?

If you are just getting started and need help developing a safety program, DKC can guide you through the process.